How to Scientifically Cut Polyurethane Foam

- 2026-01-16

- HK & KMS Cutting Machine Manufacturers

- 248

In the field of polyurethane (PU) foam processing

A commonly misunderstood concept: density is equated with hardness.

A piece of foam that feels firm to the touch may not necessarily have a high density.

And the high-density foam may also feel quite soft.

Density is not the same as hardness.

Correct understanding is the starting point for ensuring efficient and precise cutting.

The density of the foam ultimately determines the selection of the cutting process.

Understanding density is the prerequisite for mastering all cutting techniques.

I. Density Determines the Cutting Tool

Choose the right cutting tool—foam density cannot be overlooked.

1.Cutting of low-density foam

Low-density foam has a porous internal structure with a large surface area in contact with air, making its material feel “softer.”

The key to cutting it lies in achieving a clean cut surface and avoiding tearing.

Best tool: toothless blade.

It delivers the cleanest, smoothest cut surface, eliminating the need for secondary finishing in most cases and thereby saving time and material costs.

Details:

The blade’s bevel—specifically, the grinding angle on both sides of the cutting edge—is precisely symmetrical, ensuring that the cut remains straight and maximizing material utilization.

2. Cutting high-density, high-resistance foam

High-density foam is more durable, but it also offers greater resistance when being cut. For this type of foam—or for foams with a hard outer skin or containing wear-resistant chemical additives such as flame retardants—higher cutting force is required.

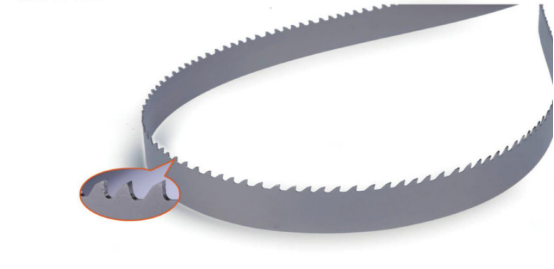

Best tool: Serrated blade

Its serrations can more effectively “bite into” and separate dense foam structures.

Tooth profile selection

Fine teeth: Provide a finer, smoother cut and generate less dust.

Coarse teeth: offer faster cutting speeds and can extend the blade’s service life when cutting abrasive materials.

In special cases, tooth height can be adjusted by grinding to optimize cutting performance on different materials.

II. Cutting methods ranging from straight to irregular shapes

Once the tool has been determined, the next step is to select the cutting process based on the product’s shape.

All industrial cutting methods for polyurethane foam can be categorized as follows:

2.1 Straight Cutting

Suitable for products requiring regular geometric shapes, there are mainly three approaches:

2.1.1 Vertical Cutting: The blade moves perpendicular to the ground.

Large-scale: Cutting large foam blocks into standard-thickness sheets. Common machine types include vertical machines that perform cutting from top to bottom and across the width.

Small-scale/precision: By using a cutting machine with an adjustable blade angle, you can achieve precise cuts of shapes with beveled edges, such as triangles and trapezoids, simply by changing the blade angle.

2.1.2 Horizontal Cutting

The tool moves horizontally, primarily used to cut thick foam blocks into continuous thin sheets.

Applications: This method can be used to produce everything from sheets of varying thickness for mattress padding to ultra-thin foam fabrics used for garment linings or quilting.

Trimming/Cutting: Remove the naturally formed skin or irregular edges of the foam block—typically by combining vertical and horizontal cuts. Complete the cleaning of all surfaces in one go.

2.2 Irregular Shape Cutting

When the product involves curves, surfaces, or complex three-dimensional shapes, the following methods should be employed:

2.2.1 Manual Cutting

Workers make cuts along a physical template. This method has low equipment costs and is commonly used by DIY enthusiasts. However, it suffers from low production efficiency, poor consistency, and significant human error.

2.2.2 CNC Cutting

Import the digital drawings into the computer, and let the machine automatically perform the cutting.

High precision and excellent repeatability make it ideal for complex graphics and mass production, significantly reducing labor costs and boosting efficiency.

It is the core equipment for achieving automation and intelligent upgrades.

2.2.3 Compression Cutting

The mold, driven by hydraulics, stamps and forms the foam in a single operation.

An efficient method suitable for mass production of specially shaped components (such as packaging liners and egg-crate-style soundproofing cotton). Roll-forming also falls into this category and is used to manufacture three-dimensional structures like corrugated shapes.

2.3.4 Milling

Carve the foam into a three-dimensional,sculpture by rotating the cutting tool.

For example, creating a perfect spherical foam ball.

Milling can remove material to create true 3D three-dimensional shapes.

III. Summary

Scientific cutting begins with accurate communication of needs.

When consulting and communicating, please provide the type of foam you’re using and the size of your facility, etc.

Our engineers will provide you with the best solution.