CNC Foam Cutting Machine | Intelligent Layout

- 2026-01-21

- HK & KMS Cutting Machine Manufacturers

- 65

01 Advantages of CNC Foam Cutting Equipment

Say goodbye to molds.

Using vibration knife technology, you only need to import the blueprint to start cutting—enabling seamless digital production from design to finished product and supporting customization of various graphics.

High precision, high efficiency.

Equipped with high-precision linear guides. Combined with Japanese-imported motors, overall production efficiency is increased by more than five times, shortening order delivery times.

Safe and convenient, worry-free and durable.

The entire machine is equipped with multiple safety protections and an anti-static system, ensuring the safety of both personnel and equipment. The overall operation has been simplified, reducing reliance on skilled workers and making production faster and management easier.

Flexible and versatile

Supports cutting of any complex irregular-shaped patterns, allows flexible tool changes to handle a variety of materials, and expands your business scope.

02 Smart Layout

Smart typesetting system: Simplify complex operations, making efficiency and precision within easy reach.

Step 1: One-click import

CAD drawings completed by the designer can be directly dragged into the system. The system automatically recognizes the graphic outlines and reads them with precision.

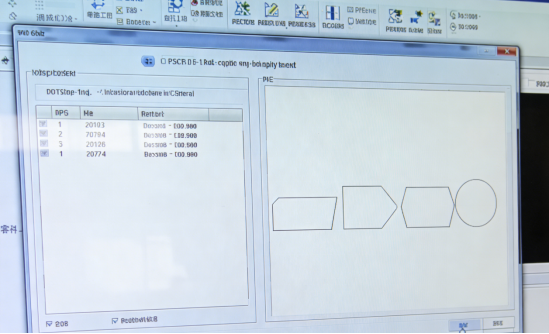

Step 2: Check the box to enter numbers.

Check all the part shapes you need to cut in the graphic list and enter the required quantity for each. The system will intelligently compile the information, preparing it for efficient layout.

Step 3: Set boundaries, intelligently optimize.

Enter the actual dimensions (length, width, and height) of the foam body to be cut, and define the “canvas” for layout. Click “Start Layout,” and the system’s core algorithm will immediately begin running.

Step 4: Global Optimization

The system is centered on the core objective of maximizing material utilization.

Simultaneously consider both the shortest total cutting path length (to increase speed) and process feasibility.

Automatically generate the optimal part layout plan.

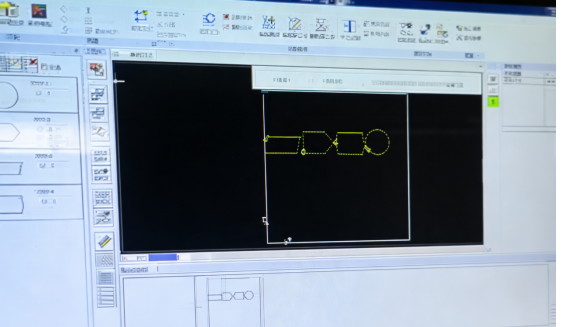

Step 5: Generate the path, with support for fine-tuning.

Based on the final layout plan, the system generates an efficient and continuous cutting path. This path can be saved locally for easy management and reuse. Operators can perform a final review in the visual interface and make appropriate fine adjustments based on their cutting experience.

Achieve a perfect integration of "artificial intelligence" and "human experience."

Finally, after confirming everything is correct, press one button to start the cutting process. The equipment will execute the cutting operation strictly according to the optimized path.

03 Advantages of Intelligent Typesetting

Smart typesetting not only simplifies operations but also delivers tangible business value.

Material costs have decreased.

By using a global optimization algorithm, material utilization can be improved by 15% to 30%. For companies engaged in long-term, large-scale production, this directly translates into substantial savings on raw material costs.

Production efficiency has surged significantly.

Typesetting and calculation tasks that previously might have taken hours can now be completed in just a few minutes. Production preparation time has been significantly reduced, the proportion of effective cutting time for equipment has greatly increased, and order delivery has been accelerated.

Lowering the threshold and reducing human error

By reducing reliance on the special expertise of operators, new employees can quickly produce near-optimal typesetting solutions. At the same time, this effectively eliminates errors arising from manual calculations and manual typesetting, ensuring batch consistency.

Summary

From import to cutting, the intelligent layout system not only addresses the question of “how to cut,” but also provides a fundamental answer to the core question: “How can we cut efficiently using the least amount of material and at the fastest speed?”

For our customers in industries such as furniture, automotive interiors, and packaging, this means having greater confidence in enhancing cost advantages and response speed.

Welcome to contact us and experience it firsthand. Try out the machine with sample cuts—let the finished products do the talking.