EPS Foam Cutting Machine Cutting Method And Daily Inspection

- 2022-05-19

- HK & KMS Cutting Machine Manufacturers

- 608

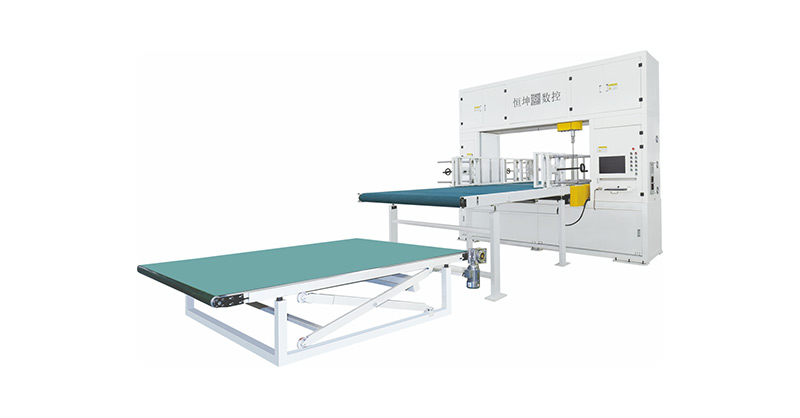

The eps line cutter is a computer-controlled machine that can cut eps material in three-phase coordinates. By using a computer-controlled micromotor to move, the corresponding cutting function is completed under the cutting of the heating wire. Accuracy control allows the machine to cut almost any given shape. The thickness of the cut is the same as the thickness of the material used. By designing and cutting a different workpiece interface, it can also produce complex three-dimensional materials with a very wide range of applications.

The eps line cutter is a sophisticated CNC machine that can cut the EPS foam into any shape of decorative lines. According to the computer input graphics, the servo motor drives the heated electric cutting wire and the working platform to move simultaneously in the X-axis and Y-axis directions to cut the foam horizontally and vertically, so that the foam material can be quickly and accurately cut. Each of the eps line cutters has five precision servo motors that control the movement of the platform and high-performance nickel-chromium alloy heating wires.

EPS Foam Cutting Machine for daily inspection:

1. Check if there are garbage in the total air intake of the EPS foam cutter and whether the valves and pressure gauges are working properly.

2. Check if all pipe joints are loose and all pipes are not damaged. If necessary, tighten or replace them.

3, check all the transmission parts for loosening, check the gear and rack meshing conditions, if necessary, adjust.

4. Check the clamping block, whether there is looseness of the steel belt and guide wheel and the elasticity of the steel belt, and adjust if necessary.

5. Loosen the tightening device and push the pulley by hand. It should be able to come and go freely. If there is any abnormality, it should be adjusted or replaced in time.

6. Check if the connector is loose (For specific operation, please refer to the relevant electrical instructions) Check the performance of all the buttons and selector switches, replace the damaged ones.

7. Check the strong cabinet and operating platform. Check if the fastening screws are loose. Use a vacuum cleaner or a hair dryer to clean the cabinet dust.

We have a variety of CNC Oscillating Blade Foam Cutting Machines for sale, you can choose according to your different needs, then consult us. Choose different sponge cutting machines according to different sponge materials, including Oscillating Vertical Blade Foam Cutting Machine and Oscillating Horizontal And Vertical Blades Foam Cutting Machine. For your convenience, we have Oscillating Horizontal Blade Foam Cutting Machine With Revolving Table for sale, please click our website for more details.

Related Information

-

The 7th China Rigid Foam Technology Annual Conference: Only by understanding foam can you build a great foam cutting machine.

-

Shipping & Holiday Stock-Up Reminder

-

CNC Foam Cutting Machine | Intelligent Layout

-

How to Scientifically Cut Polyurethane Foam

-

Industrial Applications: KMS CNC Foam Cutting Machine

-

KMS: Empowering Indian Enterprises to Seize the Billion-Dollar Market Opportunity